alta velocidad y polivalente

Los molinos planetarios son ideales para la molienda ultrafina de materiales duros, semiduros, blandos, quebradizos, viscosos y húmedos. El material a moler se tritura en su mayoría mediante impacto de alta energía por medio de bolas de molienda en vasos de molienda rotativos.

La molienda se puede realizar en seco, en suspensión o bajo gas inerte. Además de para moler, los molinos planetarios se pueden emplear para mezclar y homogeneizar emulsiones y pastas o para aleaciones y activaciones mecánicas en la investigación de materiales.

-

Alta tecnología - Molinos planetarios premium line

- Molienda a velocidad extremadamente alta hasta el rango nanométrico

- Número de revoluciones de los tarros de molienda hasta 2200 rpm

- Vasos de molienda encajados con la revolucionaria tecnología SelfLOCK, evita una sujeción adicional y un manejo inadecuado

- Comprobación automática del bloqueo del vaso en el molino

- Moler nunca había sido tan seguro como mediante el revolucionario sistema de fijación ServoLOCK de los tarros de molienda: sin sujeción adicional ni riesgo de errores de manejo

- Detección inteligente de los tarros mediante el chip RFID

- Software MillControl para el control automático del molino y la verificación de la molienda

- Se otorgaron 5 patentes para la Molinos Planetarios PULVERISETTE 5 premium line por la Oficina Alemana de Patentes

-

Polivalentes - Molinos planetarios classic line

- Molienda rápida incluso por debajo de 1 μm

- Hasta 800 rpm

- Sujeción segura del vaso con el sistema Safe-Lock

- Manejo sencillo y ergonómico así como fácil limpieza

- 7 materiales diferentes para vasos y bolas de molienda para evitar el molesto desgaste

BÚSQUEDA DE PRODUCTO

Otros Rotor / Beater Mills

OTROS GRUPOS DE PRODUCTOS

Cross Beater Mill - cast iron grinding insert

PULVERISETTE 16

-

OVERVIEW

The fast mill for all tasks

With a freely adjustable rotor speed of 2,000 – 4,000 rpm, the FRITSCH Cross Beater Mill PULVERISETTE 16 is the ideal universal mill for fast and gentle pre-crushing and fine-grinding of medium-hard, brittle materials up to a Mohs hardness of 6 in laboratories, pilot plants and industry.

Comminution can take place batchwise or continuously. The maximum feed size for bulk solids is up to 25 mm. For batchwise operation, a 5 litre collecting vessel with filter hose is delivered as standard. A 30 litre collecting vessel with filter hose is also available for larger quantities. The final fineness depends on the selection of the bottom sieve and the breaking properties of the respective material. A final fineness of < 100 μm can often be achieved after the first step due to the powerful drive and a rotor speed of up to 4,000 rpm.

The PULVERISETTE 16 offers highest operational safety: if the quick-clamping lock is opened unintentionally, a safety switch activates the motor brake so that the rotor comes to a stop. -

WORKING PRINCIPLE

Impact, friction, shearing

Comminution in the Cross Beater Mill takes place through impact, friction and shearing forces. The feeding funnel guides the grinding material directly into the centre of the grinding chamber, where it is comminuted between the cross beater and the teeth of the grinding insert. The selected bottom sieve determines the final fineness. The rotating cross beater also creates airflow through the funnel that accelerates the discharging of the ground sample into the collecting vessel. The supplied filter hose can be integrated here to effectively reduce the release of fine dust.

-

FEATURES

- Max. feed size 25 mm

- Final fineness < 100 μm already in the first step depending on the material

- Ideal for the comminution of coal, coke, lime or slate

- Perfect for fast work with a high throughput

- Easy-to-change bottom sieves with perforations sizes of 0.12-10 mm

- Easy cleaning due to grinding tools that are removable without tools

- Speed adjustment for different applications

- Batchwise or continuous operation possible

- Practical grinding chamber quick-clamping lock

- Easily replaceable impact plates

- 1.1 kW three-phase motor with frequency converter, adjustable speed of 2,000-4,000 rpm (in 200 rpm steps)

- Toothed grinding tools made of cast iron

- Trapezoidal and round perforation bottom sieves made of stainless steel in various sizes

- Useable as a table-mounted or free-standing instrument with support stand (order separately)

- Extensive accessories for simplifying your daily work

-

EQUIPMENT / ACCESSORIES

Configure your Cross Beater Mill PULVERISETTE 16 exactly to your specific application

The Cross Beater Mill PULVERISETTE 16 is equipped with a grinding insert and cross beater made of cast iron, and impact plates made of hardened steel. Also included is a stainless steel 5 litre collecting vessel with filter hose and a bayonet lock that ensures an especially convenient and dust-free connection. The bottom sieve must be ordered separately.

Bottom sieves made of stainless steel with trapezoidal and square perforation determine the final fineness of the sample. In general, the finer the desired final fineness, the smaller the perforation of the bottom sieve should be; the larger the perforation, the higher the throughput.

For batchwise operation, a 5 litre collecting vessel with filter hose is delivered as standard. A 30 litre collecting vessel with filter hose is also available for larger quantities. The PULVERISETTE 16 can be easily fixed to a table or the FRITSCH Universal support stand may be ordered.The Cross Beater Mill PULVERISETTE 16 is also available with a grinding insert made of harder stainless steel

Details PULVERISETTE 16 with grinding insert made of stainless steel

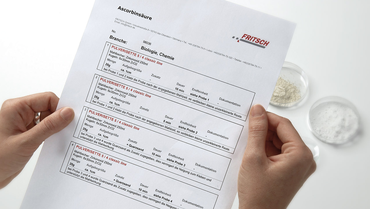

Descargas

Prospecto de Molino planetario premium line

para Molino planetario PULVERISETTE 5, Molino microplanetario PULVERISETTE 7 premium line

Prospecto de Molinos planetarios classic line

para Molino planetario PULVERISETTE 5, Molino monoplanetario PULVERISETTE 6, Molino microplanetario PULVERISETTE 7 classic line